The world of abrasive grit can be very confusing with a variety of products each with a variety of sizes, and all with their different uses. There are also plenty of variables to look at when choosing a grit such as equipment, profile requirement, environmental factors.

This blog i will try and give you some insight on how to choose the appropriate grit for you, rather than too many trial and errors.

-

- Firstly to split the abrasive world in half a simple question would be are you using a blast room/cabinet where you can recycle the grit or are you blasting the grit in say an outside environment where the grit will be blasted with once, and then spent? This question will therefore throw you down the expendable abrasive group or the re-useable group. The later being more expensive although in some cases the same grit can be used up to 14+ times therefore providing more efficiency/cost effectiveness then the expendable abrasives.

-

- Next question, what are you blasting? This requires looking at the hardness/softness of the material being blasted. A soft wood such as oak beams would require a softer grit such as Aluminium silicate, where as a steel gate would need a harder grit such as Iron Silicate. Blast rooms/ cabinets most commonly use aluminium oxide for metal objects such as automotive parts, however if the objects are heavily corroded a stronger grit such as chilled iron/steel grit may be more favourable.

-

- Once the application of grit has been decided and the product material assessed, therefore grit type determined, the next question would be size. Unfortunately lots of different abrasives all work to different units of measurement. Aluminium oxide is measured in Fepa, Garnet is in Mesh sizes, most expendables are in mm. On the website there is a conversion table which will help convert most sizes into mm for ease and comparability. There are a few industries/applications where size is generally generic for example waterjet cutting is mainly 80# Garnet. Alloy wheels preparation generally require the coarser grades of aluminium oxide F70 upwards. For expendable abrasives the more soiled the material the coarser the grit required and a medium grade would be best suited. For lighter work where the material is more precious/less corroded a finer grade would suit, such as the restoration of vintage cars. The result of the blast will vary between blasters using the same size grit due to equipment, psi, and substrate. Unfortunately this part then works its way to trial and error however if you give us a call we will certainly get you on the right path, to the ideal size and type requirement.

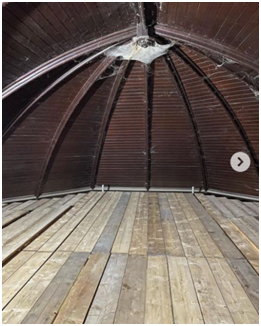

For Example in these pictures taken from a job carried out by Anglian Blasting Ltd

Question 1 – can the grit be reused after application? – No therefore expendable grit required

Question 2 – What is the material? With this being wood i would treat this as a soft material so require a soft grit

Question 3 – What size is required? As this material has a thick layer of paint it would need a medium soft grit

Answer – Aluminium silicate 0.09 – 0.5mm / Glass grit Fine

Pictures courtesy of Anglian Blasting Ltd

February 13th, 2024 by Key Abrasives

Posted in Uncategorised